What Is Multimodal Transport? Core Concepts and Key Components

Definition and Concept of Multimodal Transportation

Multimodal transport integrates multiple transportation modes—such as road, rail, sea, and air—under a single contract managed by one provider responsible for the entire shipment. This approach streamlines coordination, ensuring seamless transitions between modes without requiring shippers to negotiate separate agreements.

How Multimodal Transportation Differs from Intermodal and Single-Mode Logistics

Intermodal logistics definitely works with multiple transportation methods too, but usually comes with separate contracts for every segment of the journey plus all those container swaps between different carriers. Multimodal transport is quite different though. Everything runs under a single contract which cuts down on the mountain of paperwork and those frustrating delays when containers get stuck during transitions between companies. Let's face it, sticking to just one mode like trucks alone just doesn't cut it for most long hauls. The costs start climbing way too fast when distance becomes a factor.

Key Components: Pre-Haul, Long-Haul, and End-Haul Logistics

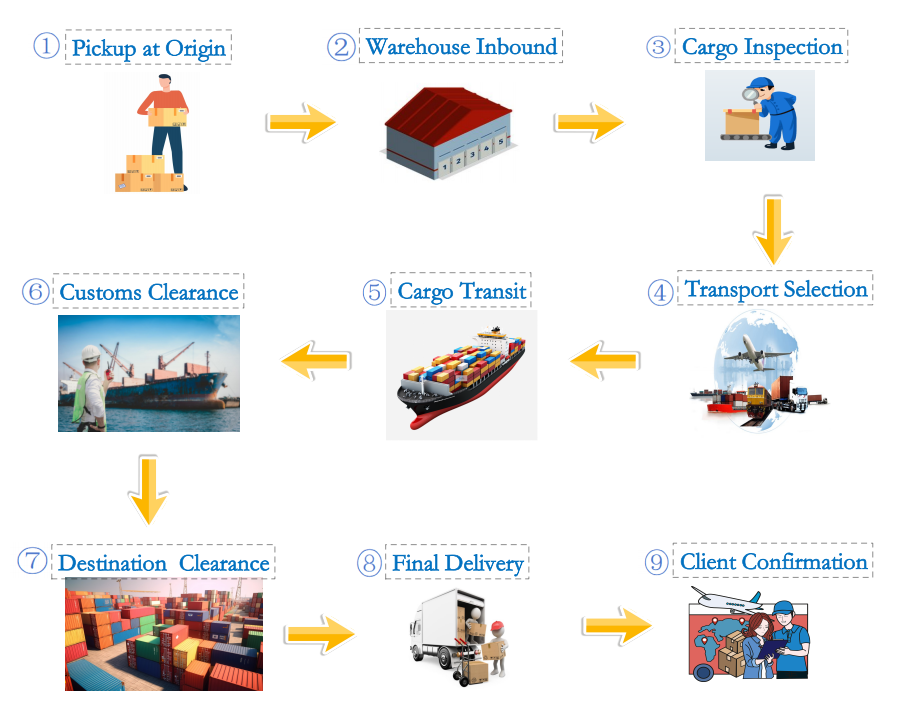

Multimodal operations are structured into three phases:

- Pre-haul: Initial collection via truck or short-distance rail

- Long-haul: High-capacity movement by rail or sea

- End-haul: Final delivery by road

This division minimizes handling delays and optimizes cost-efficiency across the supply chain.

Cost Reduction Benefits of Multimodal Transport Networks

Transportation Cost Reduction Using Integrated Transport Networks

Multimodal transport reduces logistics expenses by combining transport modes to leverage their strengths. Rail, for instance, handles long-haul bulk shipments at 50–60% lower cost per ton-mile than trucks, while short-haul trucking ensures precise last-mile delivery. Optimized networks cut fuel consumption by 18–22% compared to single-mode systems, according to a 2024 logistics analysis.

Cost Efficiency in Multimodal Transport: Balancing Mode-Specific Expenses

Cost efficiency isn't just about cutting expenses anywhere we can; it's really about finding that sweet spot between what stays constant (fixed costs) and what changes based on volume (variable costs) across different transportation methods. Take ocean freight for instance—it's still the cheapest way to move containers across oceans at around $1,200 to $1,800 per container compared to over $4,500 when flying them instead. But here's the catch: maritime shipping takes time, so businesses need to pair it with quicker land transport solutions such as trains or semi-trucks for timely deliveries. Logistics firms that have adopted smart software systems for deciding which mode of transport works best where typically see their inventory storage costs drop somewhere between 12% and 15%. These savings come from not having to pay those sky-high prices for air freight all the time.

Data Point: Up to 30% Savings in Freight Costs With Optimized Multimodal Routing

Studies show multimodal systems can reduce total freight costs by 25–30% when routing algorithms align cargo volumes with the most economical modes. For example, shifting 40% of a 1,000-mile shipment from truck to rail lowers per-ton expenses from $0.18/mile (truck-only) to $0.13/mile—a 28% saving.

Controversy Analysis: Hidden Transshipment and Coordination Costs in Multimodal Systems

Despite these benefits, multimodal transport introduces transshipment costs averaging $80–$120 per container during mode shifts. Poorly coordinated handoffs between rail, ports, and trucks can extend dwell times by 8–12 hours, eroding 5–7% of projected savings. However, blockchain-enabled tracking systems have reduced such inefficiencies by 30–40% in pilot projects.

Time Efficiency and Transit Optimization in Multimodal Logistics

Transit Time Optimization Through Multiple Transport Modes

By combining road, rail, and air transport, businesses can leverage each mode’s speed advantages while minimizing bottlenecks. Rail excels in long-haul bulk movement, while trucks provide last-mile agility. This strategic pairing reduces idle time at transshipment hubs by 15–20% compared to single-mode systems, based on logistics efficiency benchmarks.

Real-World Transit Time Variations in Multimodal Shipments

Transit times vary by 12–48 hours depending on route complexity, though real-time tracking systems mitigate unpredictability in 85% of cases. Coastal shipments using short-sea shipping and trucking experience 22% fewer delays than all-road alternatives, while cross-border rail-truck combinations cut average dwell times by 30%.

Case Study: A Leading E-Commerce Provider’s Rail-Air Hybrid Strategy

A top retailer reduced last-mile delivery windows by 40% by routing goods through regional rail hubs before transferring to air services for final delivery. This approach shortened traditional 5-day ground shipments to 72-hour deliveries for 93% of high-priority orders.

Trend: Digital Twins and Predictive Analytics for Faster Route Planning

AI-powered route optimization models reduced planning delays by 53% in test corridors, according to a 2022 study in Multimodal Transport. Digital twins now simulate port congestion scenarios 12 times faster than manual methods, enabling dynamic rerouting before disruptions occur.

Integrating Transport Modes for Superior Supply Chain Performance

When different modes of transport work together well - roads, rails, ships, planes - it builds stronger transportation networks that cut down on delays. Some reports from 2024 suggest this kind of coordination can actually reduce waiting times by around 22%. Getting the most out of these systems means creating networks that connect regions properly while still having backup options. For instance, companies often combine rail lines for moving large volumes over long distances with truck fleets to handle those tricky final delivery points where flexibility matters most. This mix helps keep things running smoothly even when unexpected problems pop up along the way.

Network Design for Freight Transport: Maximizing Connectivity and Resilience

Today's multimodal transportation networks focus on building infrastructure that makes switching between different transport modes much smoother. When ports have those rail connections right next to them plus automated systems for handling containers, they can actually reduce the time it takes to move cargo by about thirty percent over older style facilities. The industry is also starting to rely more on some pretty advanced tech these days. Things like artificial intelligence powered simulation models are becoming common tools to find the best spots for cross docking operations and transshipment points. This helps keep shipping routes running even when there are problems like bad weather hitting critical areas or unexpected labor issues causing delays at major hubs.

Strategy: Synchronizing Scheduling and Handoffs Across Modes

Success hinges on aligning schedules through:

- Digital freight platforms that sync real-time location data across carriers

- Standardized protocols for container transfers between ships, trains, and trucks

- Buffer time optimization to minimize wait times without overstocking hubs

Industry Paradox: High Integration Potential vs. Fragmented Operational Control

According to PwC's 2023 report, around three quarters of logistics companies recognize that multimodal transportation systems make things run better. But there's still a problem with how different carriers work together. The rail folks want big volumes and predictable schedules, whereas truckers care more about getting stuff delivered fast and being able to adapt when needed. This mismatch creates all sorts of delays at loading docks and distribution centers across the country. That's why we're starting to see neutral logistics platforms pop up. These middlemen help sort out the differences by sharing information between carriers and setting up incentive programs based on actual performance metrics rather than just promises on paper.

Best Practices and Real-World Applications of Multimodal Transport

Best practices for efficient multimodal logistics (planning, technology, relationships)

Getting multimodal logistics right takes careful planning, good tech tools, and solid relationships with carriers. The first step is usually figuring out which routes work best for different kinds of goods. For instance, rail makes sense for things like coal or grain that don't need fast delivery, whereas trucks handle perishables or urgent shipments better. A good TMS platform helps keep everything running smoothly between different carriers, plus it's smart to build some extra capacity into the system just in case something goes wrong with a shipment. Companies that bring together folks from operations, procurement, and finance tend to get better deals when negotiating rates. They also make sure contracts have clear penalties if carriers miss their service targets, which keeps everyone accountable in the long run.

Role of real-time tracking and IoT in enhancing accountability

IoT-enabled real-time tracking closes visibility gaps during mode transitions. GPS-equipped containers and blockchain-secured documentation reduce disputes over shipment conditions by 47% (Ponemon 2023). Sensors monitoring temperature, shock, and humidity allow proactive rerouting of perishable goods. These advanced tracking solutions also automate customs clearance by sharing verified data directly with border agencies.

Leveraging AI for dynamic routing in multimodal networks

Smart systems look at past transportation records, weather forecasts, and how busy ports get to figure out better shipping paths as things happen. A car company saw their border wait times drop around 30 something percent after they started using these computer models that guess where inspections might back up. What happens next is pretty cool too the software shifts goods away from crowded train stations over to boats that aren't being used much, so companies save money while still getting stuff delivered on time. No one has to press any buttons or make decisions manually anymore.

Real-world examples of multimodal transport success (IKEA, Amazon, auto manufacturers)

The IKEA supply chain across the globe mixes container ships for crossing oceans, switches to electric trucks when moving goods from ports to warehouses, and sets up customer pickup spots to keep those final delivery costs down. Their approach has actually cut back on wasted container miles by about 28 percent. Looking at another angle, one big name in online shopping has been using local air freight centers combined with suburban train lines to slash what they spend on same day deliveries. This cuts costs by around 19% when compared against relying solely on trucks for everything.

FAQ

What is multimodal transportation?

Multimodal transportation uses multiple modes of transport, like road, rail, sea, and air, under one contract managed by a single provider responsible for the entire shipment.

How does multimodal transport differ from intermodal logistics?

While both use multiple transportation modes, multimodal transport operates under a single contract, simplifying coordination compared to the multiple agreements usually involved in intermodal logistics.

What are the key benefits of multimodal transportation?

Benefits include reduced costs by optimizing transportation modes, enhanced time efficiency, and improved supply chain performance through integrated networks.

Are there any drawbacks to multimodal transportation?

Yes, there can be hidden transshipment and coordination costs, and poorly organized handoffs can lead to delays.

What technologies enhance multimodal logistics operations?

Technologies like real-time tracking, IoT sensors, and AI for dynamic routing help improve efficiency, accountability, and cost management in multimodal logistics.

Table of Contents

- What Is Multimodal Transport? Core Concepts and Key Components

-

Cost Reduction Benefits of Multimodal Transport Networks

- Transportation Cost Reduction Using Integrated Transport Networks

- Cost Efficiency in Multimodal Transport: Balancing Mode-Specific Expenses

- Data Point: Up to 30% Savings in Freight Costs With Optimized Multimodal Routing

- Controversy Analysis: Hidden Transshipment and Coordination Costs in Multimodal Systems

- Time Efficiency and Transit Optimization in Multimodal Logistics

- Integrating Transport Modes for Superior Supply Chain Performance

- Best Practices and Real-World Applications of Multimodal Transport

- FAQ